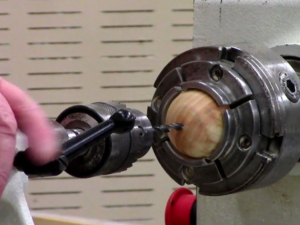

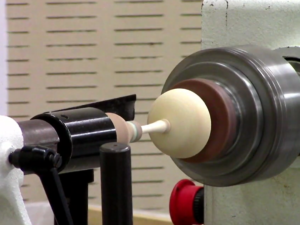

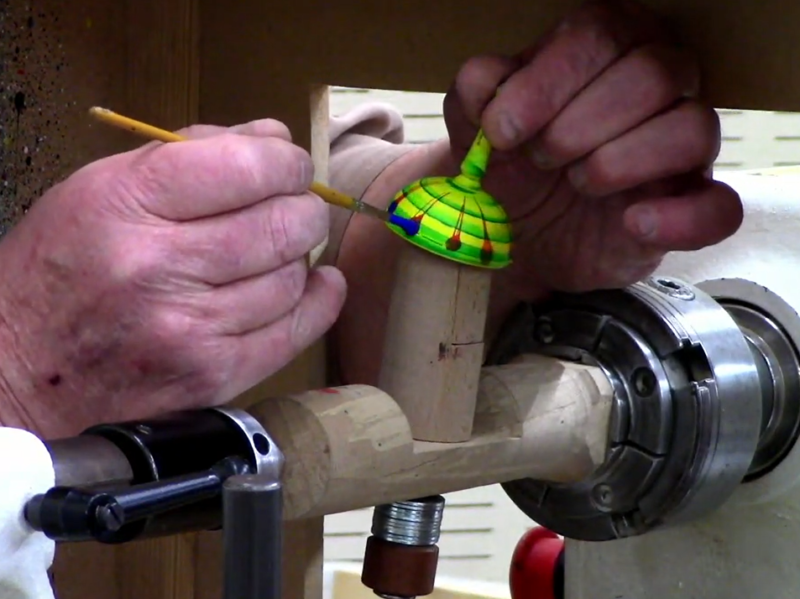

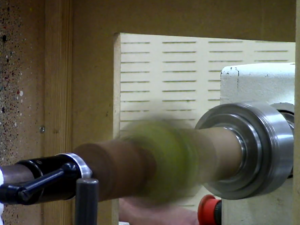

I am able to provide Woodturning Demonstrations for your club or society My demonstrations are tailored to your needs and can be of any length. I can provide all equipment and have Public liability insurance. my evening demonstrations to woodturning clubs are normally of 2 Hours duration and have a set theme. The most popular subjects are a 90 piece segmented bangle with inlaid copper, a spinning top that turns on a tower then hangs on when it stops and has an innovative decoration system that involves spinning it in a centrifuge at 2500 RPM. Another is a Japanese technique that raises bumps above the surface of a bowl and also some decorating techniques. other demonstrations are available at your request.

For more information please contact me.

Demonstration at Berkshire Woodturners